3Dpellet snack food machine

Umschalten auf2D vs. 3D Puffed Snacks: Key Differences in Production and Characteristics

1. Definition & Basic Concept

2D Puffed Snacks

- Flat, two-dimensional shapes (sheets, circles, squares)

- Examples: Rice cakes, prawn crackers, flat extruded chips

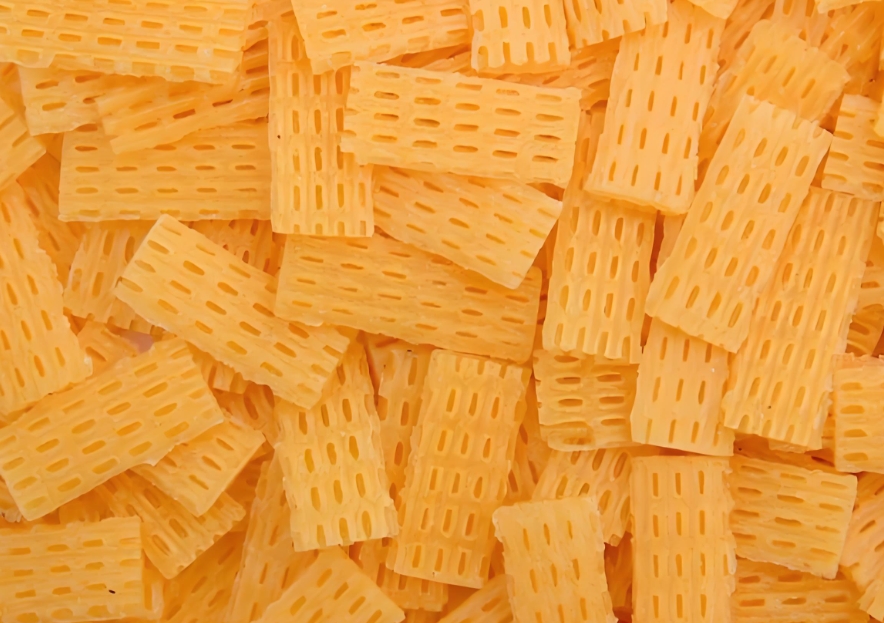

3D Puffed Snacks

- Three-dimensional structures with volume

- Examples: Cheese balls, star-shaped snacks, hollow spheres

2. Production Process Differences

| Parameter | 2D Puffed Snacks | 3D Puffed Snacks |

|---|---|---|

| Extrusion Method | Single-screw (typically) | Twin-screw (typically) |

| Würfel-Design | Flat die openings | Complex 3D mold cavities |

| Expansion | Mainly in thickness (1-axis) | Multi-directional (3-axis) |

| Feuchtigkeitsgehalt | Higher (25-30% pre-extrusion) | Lower (20-25% pre-extrusion) |

| Druck | 15-25 bar | 30-50 bar |

| Schneiden | Guillotine cutter | Rotary cutter with 3D shaping |

3. Structural & Textural Differences

2D Products:

- Struktur: Uniform density, layered

- Textur: Crispy but may be brittle

- Mundgefühl: Faster dissolution

- Öl-Absorption: Higher (larger surface area)

3D Products:

- Struktur: Hollow centers, varied wall thickness

- Textur: Crunchy with air pockets

- Mundgefühl: Longer-lasting crispness

- Öl-Absorption: Lower (protected interior)

4. Market & Consumer Appeal

| Aspect | 2D Snacks | 3D Snacks |

|---|---|---|

| Visual Appeal | Simpler presentation | Eye-catching shapes |

| Flavor Carrier | Even seasoning distribution | Trapped flavors in cavities |

| Target Audience | Health-conscious (lower fat) | Children, novelty seekers |

| Produktionskosten | Lower (simpler dies) | Higher (complex molds) |

5. Equipment Requirements

2D Production Line:

- Basic extruder with flat die

- Simpler drying conveyor

- Standard seasoning drum

3D Production Line:

- Precision twin-screw extruder

- Multi-zone shaping dryer

- Specialized coating systems for cavities

- Optical sorting for shape consistency

6. Innovation Trends

2D Developments:

- Ultra-thin crisp technology

- Multi-layer laminated structures

- Printed flavors/colors

3D Innovations:

- Interlocking snack designs

- Dual-texture products (crispy outside/soft inside)

- Shape-changing in milk (e.g., floating cereal)

Schlussfolgerung

While 2D puffed snacks dominate the healthy snack segment with their simplicity and cost-effectiveness, 3D puffed snacks command premium positioning through structural innovation and enhanced eating experiences. The choice between technologies depends on target market, product positioning, and production budget. Future advancements in die design and extrusion control will continue to blur the boundaries between these categories with hybrid 2.5D products emerging.

Would you like detailed technical specifications for specific 2D/3D snack equipment?

Ansichten posten: 503