Ivory Coast is one of the economic centers in West Africa, with strong demand for food processing. The acceptance of convenience foods by local consumers has been increasing year by year, providing a broad market for the export of small-scale instant noodle production line equipment. This article will provide a detailed introduction to the equipment and process flow of a small-scale instant noodle production line suitable for the Ivory Coast market, helping investors understand this business opportunity.

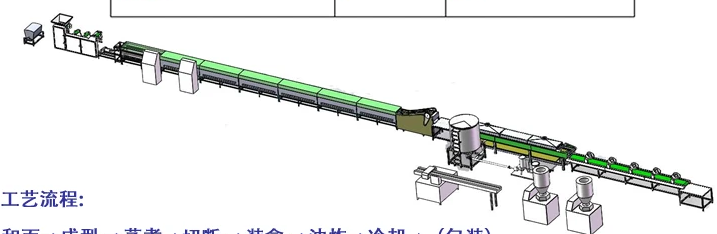

Noodle system: using a dual speed mixer to ensure thorough mixing of flour and water

Maturation process: Constant temperature and standing to allow gluten to fully form

Composite rolling: Three stage rolling to form a uniform surface sheet

Cutting and Forming: Adjustable Mold to Meet Different Specifications Requirements

Steaming and boiling process: Steam temperature should be controlled at 98-100 ℃

Quantitative cutting: The servo system ensures that the weight of each cake is consistent

Deep frying and drying: automatic temperature control oil tank, fuel consumption is 15% lower than traditional equipment

Cooling packaging: Clean packaging area equipped with ultraviolet sterilization

Power adaptability supports dual voltage of 220V/380V, suitable for the Ivory Coast power grid Capacity design of 80-100 packs per hour, suitable for small and medium-sized investors Raw material compatibility can be achieved by replacing some wheat flour with local cassava flour Convenient modular design for maintenance, key components can be quickly replaced Energy saving feature: Heat recovery system reduces energy consumption by 30%

To ensure the stable operation of the equipment in Cote d’Ivoire, we provide:

Free remote video guidance for installation

Three year warranty for key components

Two annual preventive maintenance reminders

Localized technical training services

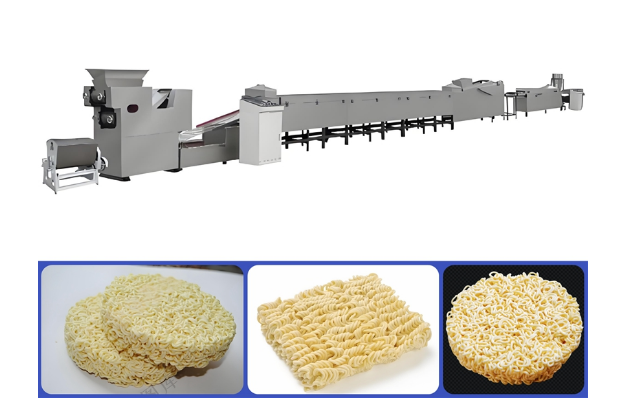

The advantages of instant noodle production line

The advantage of instant noodle production line lies in its high efficiency and automation characteristics. Through automated equipment and processes, production lines can achieve large-scale production, increase output, and maintain consistency in product quality. Meanwhile, automation of the production line can reduce labor costs and minimize errors, ensuring a more reliable and stable production process. This high efficiency and consistency enable instant noodle production lines to quickly meet market demand, while ensuring that products meet standards and enhancing enterprise competitiveness.

This small-scale instant noodle production line equipment combines practicality and economy, making it particularly suitable for the current market demand in Cote d’Ivoire. The equipment process is mature and stable, with a moderate investment threshold, making it an ideal choice for exploring the convenience food market in West Africa. For investors interested in entering this field, it is recommended to conduct small-scale trial production first, adjust the formula according to local consumer tastes, and gradually open up the market.